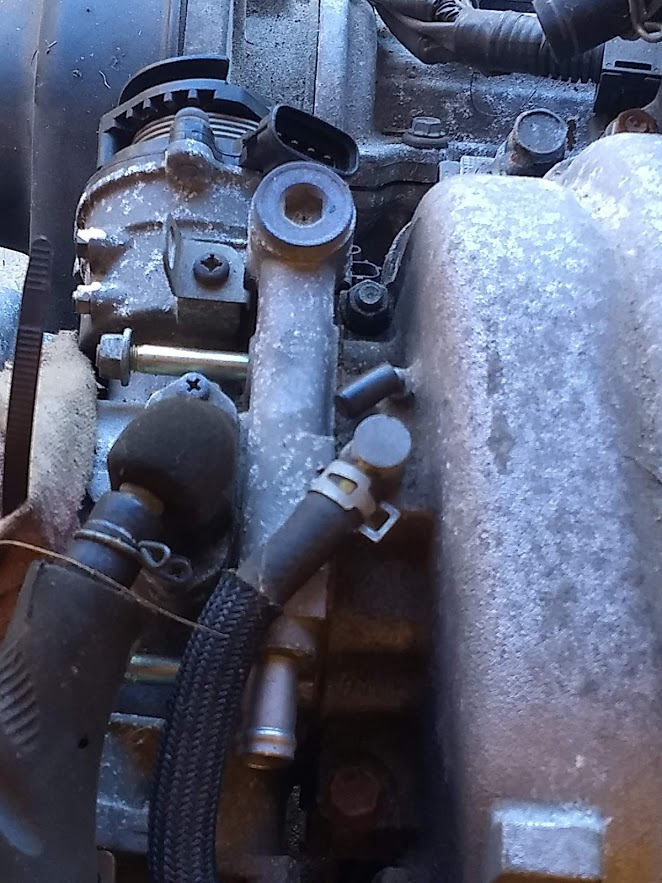

Aluminum engines can become oxidized over time, which can lead to a dull and unattractive appearance. However, there are several ways to remove oxidation from aluminum engines and restore their shine. In this article, we will explore the question “How to remove oxidation from aluminium engine?”

How to remove oxidation from aluminium engine?

Here are some step-by-step instructions on how to remove oxidation from aluminum engines based on the provided search results:

1. Clean the Engine: Before removing oxidation, it’s important to clean the engine to remove any dirt or debris that may be present. Use a mild dishwashing soap and water to clean the engine, and then rinse it thoroughly with water.

2. Apply Cream of Tartar: Cream of tartar is a cleaning agent that can be used to remove oxidation from aluminum engines. Mix cream of tartar with water to form a paste, and then apply it to the oxidized areas of the engine. Use a non-abrasive cleaning pad or a soft-bristled brush to gently scrub the paste into the aluminum. Rinse the engine with water and dry it with a clean cloth.

3. Use Aluminum Polish: Aluminum polish can also be used to remove oxidation from aluminum engines. Apply the polish to a clean cloth and rub it onto the oxidized areas of the engine. Use a circular motion to work the polish into the aluminum. Once the oxidation has been removed, wipe away any excess polish with a clean cloth.

4. Use Vinegar: Vinegar is another cleaning agent that can be used to remove oxidation from aluminum engines. Soak a clean cloth in white distilled vinegar and wrap it around the affected parts of the engine. Let the vinegar sit for 15-20 minutes, and then wipe away any remaining oxidation with the cloth. Rinse the engine with water and dry it with a clean cloth.

5. Apply Protective Coating: Once the oxidation has been removed, consider applying a protective coating or wax to prevent future oxidation. This will help to keep the engine looking shiny and new for longer.

It’s important to note that some types of oxidation may be more difficult to remove than others. If the above methods do not work, it may be necessary to seek professional help or use more specialized cleaning products.

Additionally, it’s important to take preventative measures to avoid oxidation in the first place, such as storing the engine in a dry place and avoiding exposure to harsh chemicals or saltwater.

what are some common causes of oxidation on aluminium?

Aluminum oxidation is a natural process that occurs when aluminum is exposed to oxygen. The oxidation process causes aluminum to form a hard, whitish-colored surface skin, which can lead to corrosion if not addressed. Here are some common causes of oxidation on aluminum:

1. Exposure to Oxygen: Aluminum is highly reactive and will react with oxygen in the environment to form an oxide layer on the surface. This oxide layer is what protects the aluminum from further oxidation, but it can also lead to corrosion if it is damaged or removed.

2. Exposure to Water: Water can accelerate the oxidation process on aluminum, especially if the water contains chlorides or sulfides. These compounds can attack the oxide layer and cause corrosion to occur.

3. Exposure to Other Metals: When aluminum comes into contact with other metals, such as copper, mercury, tin, nickel, and lead, it can cause deposition corrosion. This type of corrosion is more pronounced in acidic solutions and can lead to the breakdown of the oxide layer on the aluminum.

4. Exposure to Extreme pH Levels: High levels of pH can break down the oxide layer on aluminum, leading to corrosion. To avoid corrosion, untreated aluminum should be used in areas with a pH of between 4.5 and 8.5.

5. Galvanic Corrosion: Galvanic corrosion occurs when aluminum comes into contact with other metals in the presence of an electrolyte, such as saltwater. This can cause the aluminum to corrode more quickly than it would on its own.

To prevent or address oxidation on aluminum, it’s important to take appropriate measures, such as applying a protective coating, minimizing exposure to water and other metals, using compatible metals, and implementing a regular maintenance schedule to inspect the aluminum for any signs of corrosion.

how long does it take to remove oxidation from aluminium using vinegar?

The time it takes to remove oxidation from aluminum using vinegar can vary depending on the severity of the oxidation. According to the provided search results, vinegar can be an effective cleaning agent for removing oxidation from aluminum engines.

Here are some general guidelines on how long it may take to remove oxidation from aluminum using vinegar:

1. Soak Time: If you are cleaning a large aluminum surface, soak a cloth in vinegar and then wipe it across the oxidation. Let the vinegar sit for 15-20 minutes to allow it to break down the oxidation.

2. Scrubbing Time: After the vinegar has soaked for 15-20 minutes, use a soft-bristled brush to scrub the discolored areas and remove oxidation. For stubborn spots, cut a lemon in half and dip one of the halves in some salt. Then, rub the salted lemon against the oxidation. Scrubbing time can vary depending on the severity of the oxidation.

3. Rinse Time: Once the oxidation has been removed, rinse the engine with water and dry it with a clean cloth. Rinse time can vary depending on the size of the engine and the amount of vinegar used.

It’s important to note that vinegar may not be effective for all types of oxidation, and some types of oxidation may require more specialized cleaning products or professional help.

Additionally, it’s important to take preventative measures to avoid oxidation in the first place, such as storing the engine in a dry place and avoiding exposure to harsh chemicals or saltwater.

what are some other methods to clean oxidized aluminium?

There are several methods to clean oxidized aluminum, and the choice of method depends on the severity of the oxidation and the type of aluminum surface. Here are some other methods to clean oxidized aluminum based on the provided search results:

1. Methylated Spirits: Methylated spirits can be used to clean aluminum surfaces. Apply a few drops of rubbing alcohol to a clean cloth and wipe the aluminum surface. This method is particularly effective for removing light oxidation.

2. Meudon Whiting Powder: Meudon whiting powder is a slightly abrasive cleaner that can be used to remove oxidation from aluminum. Dilute the powder with water in a large container to form a liquid. Dip a cloth in the mixture and rub the aluminum surface, making sure to thoroughly clean it. Let the surface dry until the mixture is absorbed.

3. Bicarbonate of Soda: Bicarbonate of soda is a versatile cleaning agent that can be used to remove oxidation from aluminum surfaces. Mix two tablespoons of bicarbonate of soda with one tablespoon of water to form a paste. Use a sponge to scrub the oxidized aluminum surface with the paste. Rinse the surface with water and dry it with a clean cloth.

4. Tartar Cream: Tartar cream is a gel of potassium bicarbonate and water that can be used to remove oxidation from aluminum surfaces. Apply the cream over the oxidized area and let it sit for a few minutes. Use a soft-bristled brush to scrub the surface and remove the oxidation. Rinse the surface with water and dry it with a clean cloth.

5. Commercial Cleaners: There are several commercial cleaners available that are specifically designed to remove oxidation from aluminum surfaces. Make sure to choose a cleaner that is suitable for the type of aluminum surface you are cleaning. Apply the cleaner according to the instructions on the packaging and rinse the surface with water.

It’s important to note that some types of oxidation may be more difficult to remove than others. If the above methods do not work, it may be necessary to seek professional help or use more specialized cleaning products.

can you use baking soda to clean oxidized aluminium?

Yes, you can use baking soda to clean oxidized aluminum. Baking soda is an effective and versatile cleaning agent that can help remove oxidation from aluminum surfaces. Here are the steps to clean oxidized aluminum using baking soda:

1. Prepare the Baking Soda Paste: Mix two tablespoons of baking soda with one tablespoon of water to form a paste. Adjust the quantities as needed to achieve the desired consistency.

2. Apply the Paste to the Aluminum Surface: Using a soft cloth or sponge, apply the baking soda paste to the oxidized areas of the aluminum surface. Ensure that the paste covers the affected areas evenly.

3. Scrub the Surface: Gently scrub the aluminum surface with the baking soda paste using a circular motion. For stubborn oxidation, you can use a soft-bristled brush to help remove the corrosion.

4. Rinse and Dry the Surface: Once the oxidation has been removed, rinse the aluminum surface with water to remove the baking soda residue. Dry the surface thoroughly with a clean cloth to prevent water spots.

5. Apply a Protective Coating: To prevent future oxidation, consider applying a protective coating or wax to the aluminum surface after cleaning. This will help maintain the shine and protect the aluminum from environmental factors.

It’s important to note that baking soda is a mild abrasive, so it’s suitable for cleaning aluminum surfaces without causing damage. Additionally, always test the baking soda paste on a small, inconspicuous area of the aluminum surface before applying it to the entire area to ensure compatibility and to avoid any potential discoloration.

By following these steps, you can effectively clean oxidized aluminum using baking soda as a safe and affordable cleaning solution.

Helpful Resources

- https://schaumburgspecialties.com/how-to-remove-oxidation-from-aluminum-stepbystep-instructions/

- https://www.tuofa-cncmachining.com/tuofa-blog/how-to-clean-oxidized-aluminum.html

- https://www.fjcruiserforums.com/threads/oxidized-aluminum-what-is-best-to-clean.438714/

- https://www.wileymetal.com/aluminum-corrosion-why-it-happens-and-what-to-do-when-it-does/

- https://amcaluminum.ph/how-clean-oxidized-aluminum/

- https://fractory.com/aluminium-corrosion/

- https://www.thyssenkrupp-materials.co.uk/does-aluminium-rust

- https://www.wikihow.com/Clean-Oxidized-Aluminum

- https://www.trexo.ca/en/clean-oxidized-aluminum/

- https://thecorrecter.com/how-to-stop-electrolysis-on-aluminium-boat/

- https://thecorrecter.com/how-to-stop-corrosion-on-aluminium-boats/

- https://thecorrecter.com/does-aluminium-oxidize/

- https://thecorrecter.com/how-to-insulate-aluminium-window-frames/

- https://thecorrecter.com/how-to-fix-aluminium-window-hinges/

- https://thecorrecter.com/how-to-stop-condensation-on-aluminium-window-frames/

- https://thecorrecter.com/can-aluminium-be-brazed/

- https://thecorrecter.com/how-to-melt-aluminium-without-a-foundry/

- https://thecorrecter.com/is-aluminium-dust-harmful/

- https://thecorrecter.com/is-aluminium-foil-a-good-insulator-of-heat/

- https://thecorrecter.com/is-aluminium-oxide-ionic-or-covalent/

- https://thecorrecter.com/can-aluminium-be-magnetised/

- https://thecorrecter.com/is-aluminium-monatomic-or-diatomic/

- https://thecorrecter.com/is-aluminium-toxicity-reversible/

- https://thecorrecter.com/what-to-do-if-you-accidentally-eat-aluminum-foil/

- https://thecorrecter.com/can-you-put-aluminium-foil-in-an-air-fryer/

- https://thecorrecter.com/what-size-aluminium-wire-for-125-amp-service/

- https://thecorrecter.com/how-to-remove-scratches-from-aluminium-4/

- https://thecorrecter.com/how-is-aluminium-mined-2/

- https://thecorrecter.com/is-aluminium-malleable-and-ductile/

- https://thecorrecter.com/does-aluminium-cause-dementia-2/

- https://thecorrecter.com/how-to-remove-anodising-from-aluminium-2/

- https://thecorrecter.com/how-to-restore-aluminium-boat/

- https://thecorrecter.com/how-does-aluminium-cans-affect-the-environment/